We specializes in the production of various series of PVC switch junction box, PVC drainage silencing pipe fittings, PVC single vortex silencing pipe fittings, PVC drainage pipe fittings and PVC electrical fittings

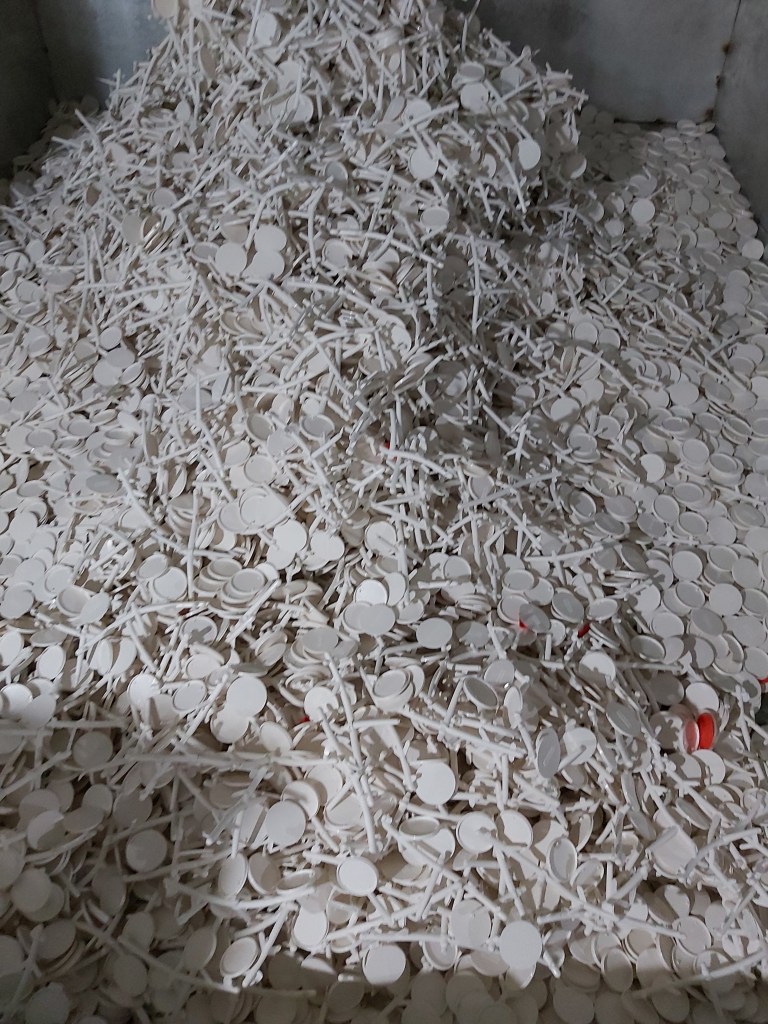

our products include, pvc barrel union ,pvc caps ,pvc couplings,pvc elbow,pvc faucet adaptor, pvc faucet elbow, pvc faucet socket, pvc faucet tee, pvc male adaptor, pvc reducing coupling,pvc reducing tee, pvc tee, pvc valve socket, pvc reducing bush spigot, pvc reducing bush spitgot, pvc tee slip

We specializes in the production of various series of PVC switch junction box, PVC drainage silencing pipe fittings, PVC single vortex silencing pipe fittings, PVC drainage pipe fittings and PVC electrical fittings

our products include, pvc barrel union ,pvc caps ,pvc couplings,pvc elbow,pvc faucet adaptor, pvc faucet elbow, pvc faucet socket, pvc faucet tee, pvc male adaptor, pvc reducing coupling,pvc reducing tee, pvc tee, pvc valve socket, pvc reducing bush spigot, pvc reducing bush spitgot, pvc tee slip

We supply pvc foam board ,pvc celluka board,pvc color foam board and lamiated pvc foam board, thinkness from 2mm-30mm, the pvc foam board we produce has good function of waterproof ,rot proof, acid resistant,non toxic,high impact strength etc.

PVC foam board can be used in the following areas, such as, bathroom cabinet, construction ,advertising and sign board, exhibition desk, shelve in supermarket, decoration for patition wall and shop windows.,architectural decoration and upholstery.

3DPrinting #AdditiveManufacturing #3DPrinter #Filament #PLA #ABS #PETG #ResinPrinting #SLA #DLP #FFF #FDM #SLS #Metal3DPrinting #Bioprinting #3DModeling #CAD #CAM #STL #GCode #Slicer #Infill #SupportStructures #LayerHeight #Nozzle #Extruder #Hotend #BedAdhesion #Calibration #Overhang #Bridge #Warping #ElephantFoot #Stringing #3DScan #ReverseEngineering #Prototyping #Manufacturing #Design #Innovation #Technology #Engineering #Materials #Polymers #Composites #Metals #Ceramics #Healthcare #Aerospace #Automotive #Education #Art #Architecture #Fashion #Jewelry #Toys #Hobbies #DIY #OpenSource #Community #Software #Hardware #Firmware #Upgrades #Troubleshooting #Maintenance #Repair #Customization #Personalization #RapidPrototyping #RapidManufacturing #DigitalManufacturing #Industry40 #MakerMovement #FabLab #3DPrintFarm #3DPrintService #3DPrintMarketplace #3DPrintMaterials #3DPrintSoftware #3DPrintHardware #3DPrintApplications #3DPrintTechnology #3DPrintInnovation #3DPrintDesign #3DPrintEngineering #3DPrintEducation #3DPrintArt #3DPrintBusiness #3DPrintFuture #3DPrintRevolution #3DPrintExpert #3DPrintEnthusiast #3DPrintTips #3DPrintTutorial #3DPrintReview #3DPrintNews #3DPrintEvent #3DPrintConference

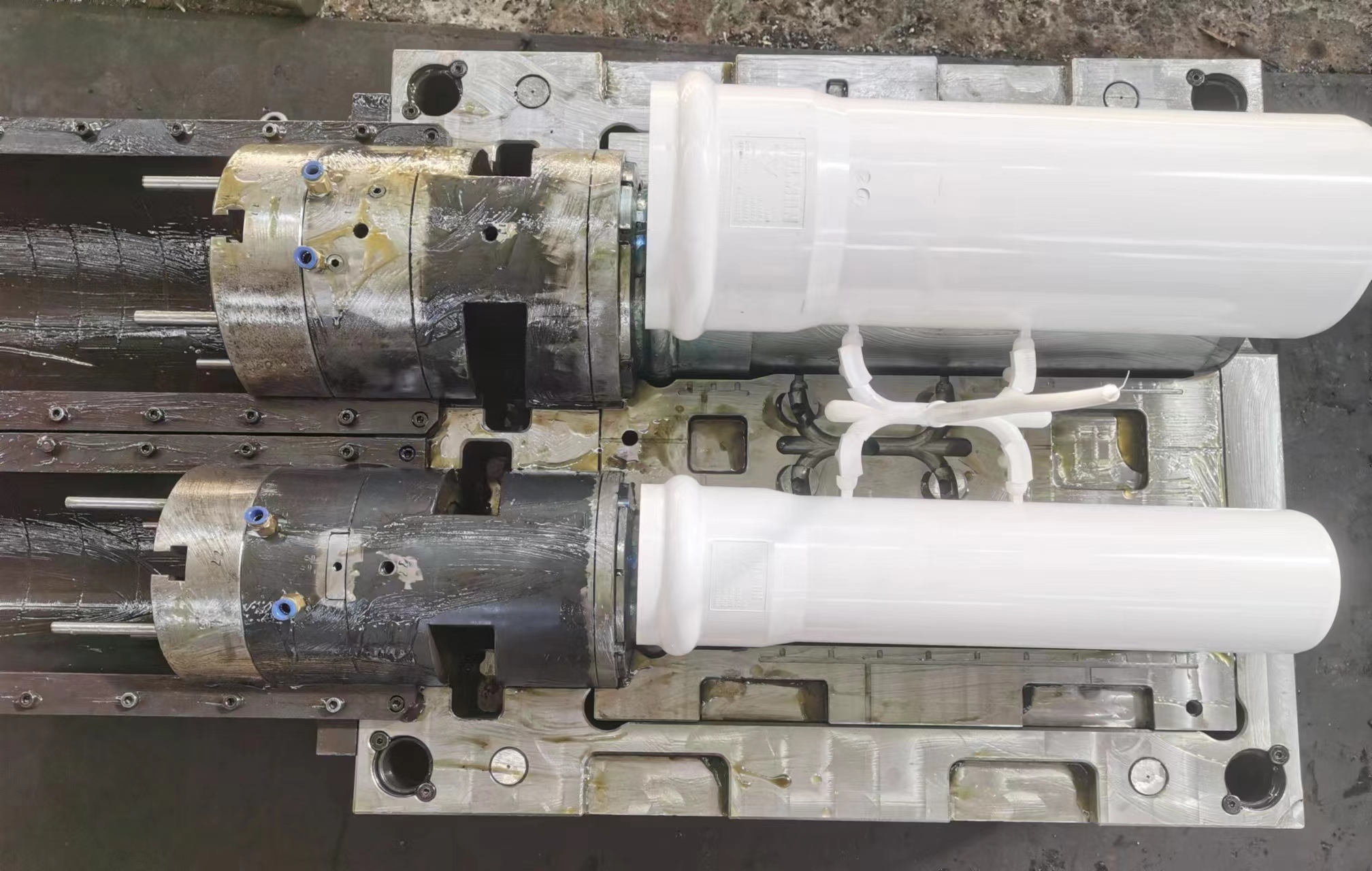

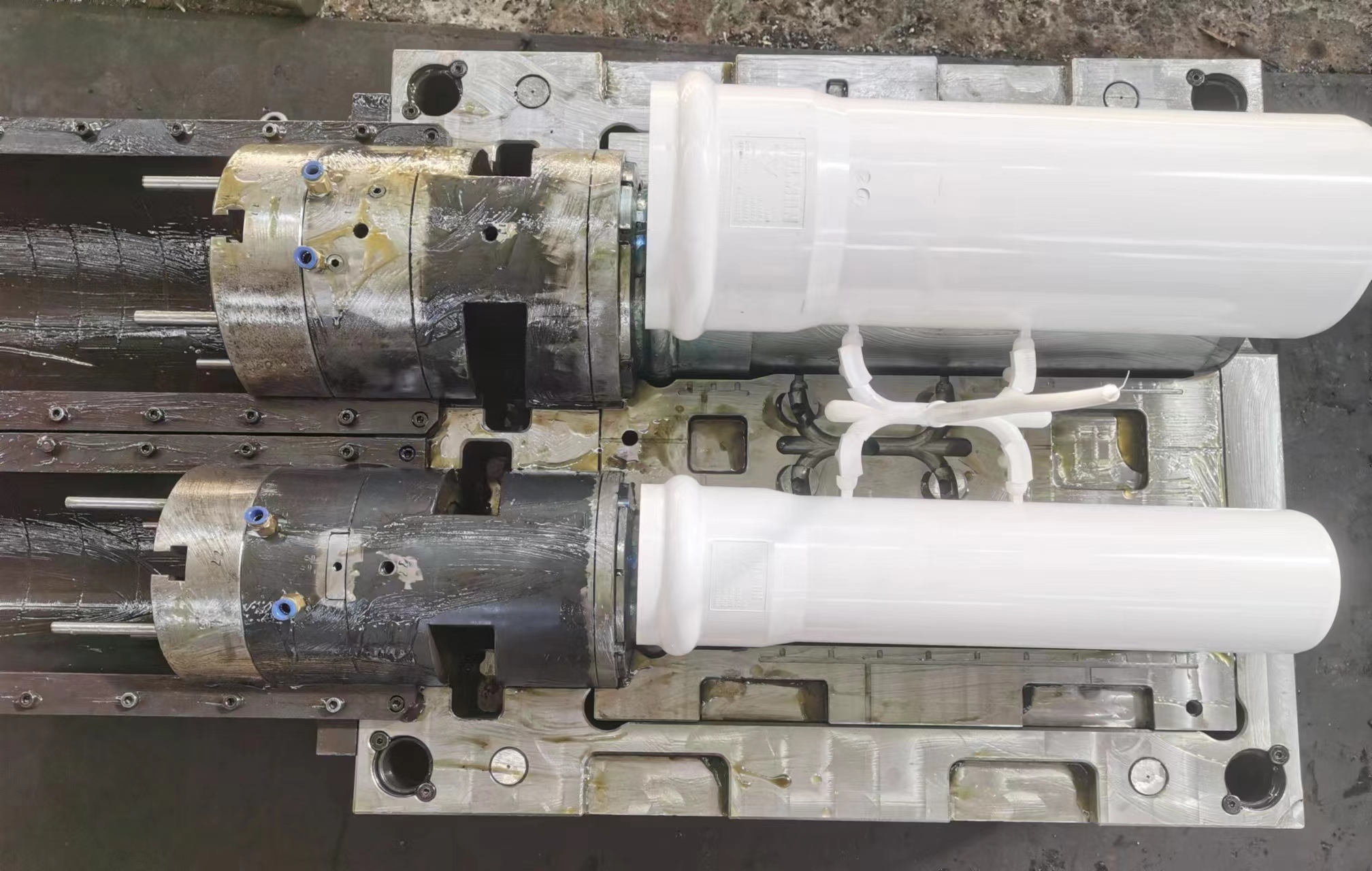

3D Printing: Revolutionizing Plastic Mold Making

3D printing, also known as additive manufacturing, has emerged as a transformative technology across various industries, and plastic mold making is no exception. Its ability to create complex geometries, reduce lead times, and lower costs has made it an invaluable tool for mold makers.

Benefits of 3D Printing in Plastic Mold Making:

The alloy base cover we made for our cusotmer, it is made by gravity casting mould,except the die casting mould, we also supply gravity casting mould to customer.